Let’s begin with the headline.

The COBRA LIMIT3D irons are the primary commercially accessible 3D printed irons.

As a result of this isn’t my first day on the web, I do know a few of you’ll learn this and assume (or scream in my remark part), COBRA is ripping-off Avoda, the small model that lately obtained some consideration for 3D printing irons for Bryson DeChambeau.

C’mon, guys. It’s not like 3D printing a golf membership is so simple as hitting the print button. Effectively, I suppose the act itself is strictly that simple however the button doesn’t work with out years of improvement.

In COBRA’s case, it has been engaged on 3D printed irons for the final half dozen years. Whereas it has saved its playing cards near its vest, COBRA has had 3D printed golf equipment on the PGA Tour for years.

Rickie Fowler and Gary Woodland have performed 3D printed COBRA golf equipment.

When Kyle Berkshire cracked the face of his conventionally made utility iron, COBRA 3D printed a brand new one.

That ought to resolve any questions you might need concerning the sturdiness of 3D printed irons.

And what about Bryson?

He performed COBRA 3D printed utility irons since 2017. He additionally performed 3D printed variations of KING TOUR irons. One would possibly surmise that his earlier expertise with COBRA is what led him down the 3D printing path along with his latest irons.

Cool story, however why is COBRA doing this?

The brief and easy reply is as a result of it could.

I’ll shout with my dying breath about how COBRA has by no means gotten the credit score it deserves as one of many sport’s nice innovators.

To an extent, that’s a necessity of its dimension however, nonetheless, the corporate has seldom been content material to do issues like everybody else.

The place’s the enjoyable in that?

3D printing advantages

What are the advantages of 3D printing? (You’ll have requested.)

In a phrase, efficiency.

It’s not that COBRA LIMIT3D irons will carry out like no iron has earlier than. You’re not going to get 10 extra yards and also you’re not going to rattle each flagstick from 150 yards however they do convey us nearer to what’s usually considered the Holy Grail of iron design.

It’s not misplaced on me that a few of you like the look of a stable game-improvement shovels however the majority of us drool at even the potential for an iron that gives the forgiveness of a game-improvement iron with the compact design footprint of a participant’s iron.

That’s what you’re getting with the COBRA LIMIT3D iron.

And for positive, COBRA isn’t the primary to say game-improvement efficiency from an iron that appears like a blade. At occasions, there was a touch of fact in that however actually what we’re speaking about are golf equipment that hid their dimension through design methods. These work to make an iron look smaller than it’s but it surely’s larger than a blade simply the identical.

You get the clear traces,however not the true participant’s form. There’s at all times been a sacrifice: dimension, really feel … usually each.

What separates COBRA’s LIMIT3D irons from the pack is that it delivers on the promise of forgiveness from a participant’s form. It’s not technically a blade however the LIMIT3D are extra compact than COBRA’s KING TOUR irons.

We’re speaking about decoupling kind and performance and, in that respect, this is perhaps the uncommon blade (or one thing like a blade) that can make you a greater ball striker.

How COBRA LIMIT3D irons are made

COBRA’s 3D printing methodology would possibly make Rumpelstiltskin proud. It’s not precisely straw into gold however the course of that turns 316L stainless-steel powder right into a golf clubhead looks like a kind of issues that shouldn’t be doable.

Full disclosure: I’d say the identical factor a couple of digicam. I imply, I take a look at one thing, click on a button after which that factor I used to be taking a look at is captured without end. How does that work?

I really feel the identical manner about utilizing laser beams to fuse powdered steel into the form of a golf membership.

At this level, should you stated sorcery was the one clarification, I’d be effective with it.

A single iron head consists of roughly 2,600 layers. The machines that kind the irons are able to printing 20 heads in 24 hours.

A fast apart: This isn’t the identical course of COBRA makes use of to make its 3D putters. It’s not a case of 1 methodology being higher or worse than the opposite. It’s simply completely different and COBRA selected the tactic most applicable for process.

Whereas a compact however extremely forgiving golf membership is the consequence, the rationale it’s doable (aside from sorcery) is that 3D printing permits designers to create geometries which can be much more complicated than what’s achievable with forging, casting or milling.

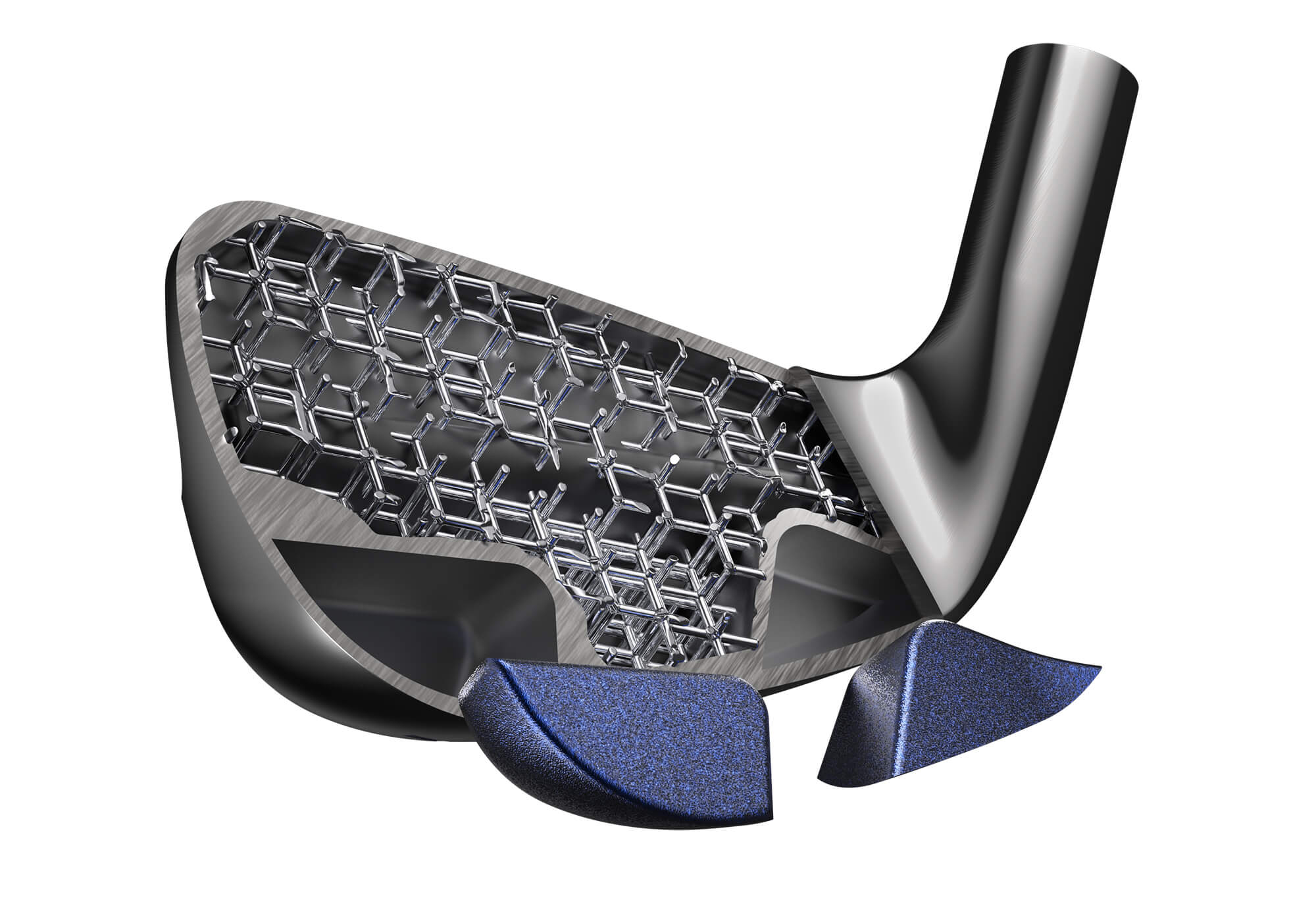

Within the case of the LIMIT3D iron, the bottom of the face is comprised of a dodecahedral lattice sample that gives the structural integrity essential to assist the face whereas saving a metric shit-ton (that’s a technical time period) of weight.

FYI: The lattice sample seen within the again cavity isn’t a part of the construction. It’s a visible cue that serves to assist inform the tech story.

In a typical stable development, the face piece or core of the membership weighs between 100 and 122 grams. COBRA’s latticed core weighs simply 9 to 12 grams relying on the loft.

Do the mathematics, guys. We’re speaking about huge financial savings.

How did COBRA reallocate that mass?

You recognize the reply. They used huge chunks of tungsten within the heel and toe (a complete of 70 to 100 grams relying on the loft) to drive the middle of gravity decrease and MOI numbers greater than any iron of their lineup.

When the mud or, I suppose, the 316L metal powder settles, what’s left with is a golf membership with a real participant’s iron form and forgiveness that surpasses game-improvement designs.

Stated one other manner: extra pace, greater launch and extra forgiveness in an eye-pleasing package deal.

COBRA LIMIT3D Efficiency

In robotic testing versus the KING TOUR, COBRA noticed almost 2 mph extra ball pace and a further 5 yards of distance with a 7-iron.

The LIMIT3D is a level stronger however the shaft is a tick shorter. A few of its pace is coming from loft, however not all of it. Increasing testing to incorporate misses, the LIMIT3D is longer nonetheless and provides tighter dispersion. So, once more, game-improvement efficiency from a membership with a Tour-sized footprint.

What about really feel?

On one hand, perhaps you shouldn’t care about really feel. On the opposite, it’s no small a part of purpose why individuals play participant’s irons.

I’ll reserve judgment till I’ve the possibility to hit the LIMIT3D however COBRA’s modal evaluation (a way to measure the frequencies of a clubhead because it vibrates and quantify really feel) suggests an iron that’s far more much like muscle-back than one thing like a participant’s distance or game-improvement iron.

A part of the promoting level is that the COBRA LIMIT3D don’t simply appear like a participant’s iron, they really feel like one, too.

COBRA LIMIT3D irons – How a lot and what number of?

As you’ve been studying alongside, chances are you’ll be pondering: These don’t sound low cost.

Eager statement, chief. They’re not. It’s not.

However should you do need them, I strongly recommend you bang the Purchase Now button the second they go on sale.

Restricted is within the title (kind of) and the irons are simply that. COBRA has restricted manufacturing to 500 units worldwide and solely 300 of these shall be accessible in the usA.

Units shall be 4-PW, RH solely, and customized solely. There isn’t a inventory shaft. Every set is constructed to spec.

The retail worth is $2,999.99. Gross sales start (and sure finish) on June 7.

A postscript in all of this: How does 3D printing translate to different classes? 3D printed prototypes exist in each membership class however the potential for development is probably going best within the driver class. The requisite dimension and power of a driver face means a major quantity of forwardly positioned mass is non-negotiable.

Aside from the USGA, the face itself is probably going the most important impediment to innovation.

What if COBRA might obtain the identical sort of weight financial savings it did with the LIMIT3D iron in a driver? Would it not make for probably the most significant breakthrough since titanium?

I requested COBRA’s VP of Innovation, Mike Yagley, if he wished to speak about how 3D printing might be leveraged in future driver designs.

“Nope.”

I feel what he meant was “not but.”

For extra data on COBRA LIMIT3D 3D Printed Irons, go to Cobragolf.com.

The publish COBRA Releases Absolutely 3D Printed LIMIT3D Irons appeared first on MyGolfSpy.